Ewan had a great visit to the far North to look at the Ullapool skiffs and reports as follows.

If we have weather like now the Skiffie Worlds will be fantastic. Ullapool was sparkling in the winter sun and a trial row in the school boat was arranged specially for me. Her official name is Cul Mor but her builders have named her “Pull” to go with her sister Ulla.

At first Topher had some problems raising a crew, as the other boats were going out later, but Jan hijacked a couple of mountaineers who were heading for Stack Polly and so Dougie and Struan got an introduction too. This seems to be one of the best things about the skiffs – they are so easy to set up and row that everyone can take part, although I admit the two pressganged climbers were pretty fit.

Ullapool rows with shortish oars, 11 feet 2 inches I think. It seems proven that oars between say 12 and 15 feet are liable to cause bumping. With short oars you sit slightly off-centre on same side as your oar; above that length you sit opposite the oar port, so 16 feet is fine if you can actually lift an oar that weight. For smaller and unfit older people like me the shorter ones are fine. If the rowing experience isn’t comfortable and unthreatening only alpha-people will take part, so don’t let’s put anyone off.

On Sunday morning I rowed two miles with light 11ft 2in oars and wasn’t out of breath. We had a great excursion down past where the Worlds will take place to an abandoned croft, where we climbed a hill and breathed in the view.

I noticed that Topher was feathering his oars, which is unusual as it isn’t easy with the kabes and pins that most skiffs have. He told me that people who have rowed before usually want to feather. New recruits don’t.

Feathering heavy oars is hard on the wrists and probably doesn’t increase speed. The intention is to reduce windage on the return. Narrow blades don’t catch as much wind as modern racing blades, so it may not make much difference.

There may be an attempt to ban feathering, but right now you can feather if you can work out a way of doing it..

This ties in with oar and oarlock design. Rectangular oars are strong, easy and cheap to make. Feathering oars need round(ish) sections where it matters.

It is extremely difficult but possible to make oarlocks in wood that allow easy feathering. It can be done with two pins if you like the noise of the constant clunking. The Cornish gigs tried feathering but I’ve heard they may have banned it.

It’s good to “gear” oars to vary length for conditions, basically ending up with more inboard in rough conditions or a small rower, extending out in calm water. You do this by adding little buttons that catch on the pins, or a pad underneath with holes to go over the pins. This is difficult with feathering oars and it ends up being down to the skill of the rower.

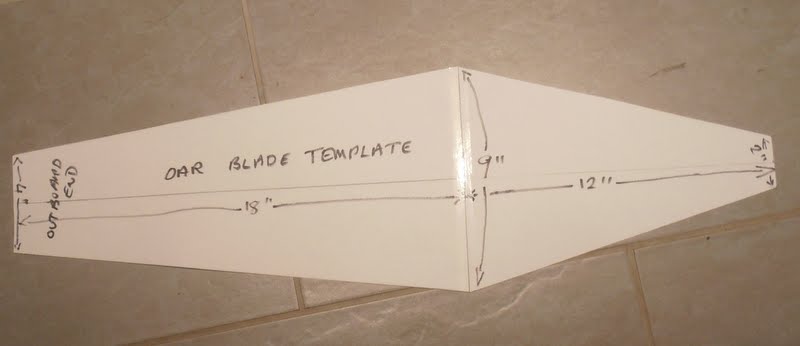

I would like to make a set of lightweight rectangular non-feathering oars 11ft 2ins. I can work up a good design for these.

Our most likely frequent competitors will be Kilmelford and some will row on both boats. Hence I’d like to persuade them to do the same as we do.

I got some information about rudders too.

There’s a discussion going on and clubs have been asked to send in a photograph of their existing rudders, just to find out what teams are doing. I’d like to keep the Seil rudder right in terms of the concept – looking traditional and “right” even if not state of the art – with the stock following the line of the aft stem, the leading edge of the blade as vertical as possible without an outrigger, the blade itself a nice hydrofoil shape. Also controlled by an oak tiller to the side with fore and aft extension, as central rudders are very uncomfortable for the cox and a yoke with strings can be tricky.

I found a great idea for low cost rudder gear – glue in end pieces from old stainless steel rigging screws, connect with stainless rod. Strong, looks good and works.

Rubbing strips along keel can be made from heavy polypropylene cut into strips. Tough and slippery with an element of “give” looks fine and works. You get a sheet and rip it up, can be profiled with a hand plane.

Launching trolleys at Ullapool are made from cheap timber, supporting the skiff at frame 6. We need two wheels and some stainless tube for axles.